0.the introduction

Because of the characteristic of the starch material itself, to realize automatic weighing and packing starch bright with ground dragon feed to it is difficult to achieve high accuracy, is more successful way of feeding the wind to send, this leads to complex mechanical parts, with electric control part relative to other quantitative weighing and packing equipment control instrument is also complex, most of the domestic existing equipment are imported,The localization is the inevitable trend.In view of this situation, a starch weighing packaging controller was developed.

1. Workflow of the system

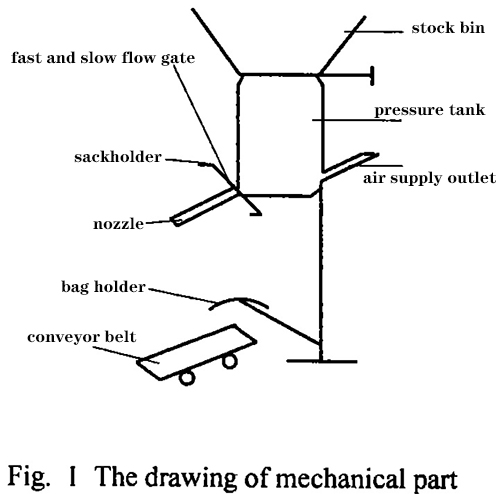

The mechanical part of the system mainly includes silo, pressure tank, fast and slow flow gate, nozzle, bag clip and bag holder. The mechanical part is shown in Fig. 1.The whole system under the control of the controller, according to the weight of starch, the site of the state switch, different action control and corresponding alarm run.The main process is as follows:

1) After starting up, the system will automatically detect the correctness of the parameters set internally. If there is any error, it will be prompted. If it is not corrected, it cannot proceed further;If there are no errors, the system can enter the hold or run state.

2) In the maintain state, users can set and access primary, secondary and tertiary data, as well as print and display some data.

3) Press the "Run" button, the system enters the running state, and the weighing system clears at the same time. If the zero deviation exceeds the set value, the system will alarm until the zero deviation is less than the set value, then the system can enter the next step and wait for the start signal.

4) Whether it can enter the weighing cycle depends on the material level of the silo and the material level of the starch in the pressure tank.When the pressure tank is satisfied, close the pressure tank. If the closure door of the pressure tank is not closed, an alarm will be generated. If the valve is not lifted, the pressure tank cannot enter the next step.

5) When the pressure tank is closed, the prompt is given, you can put the bag on the nozzle, press the button of closing and closing the bag, and the controller outputs the bag clamping action. After the action is sent, the system will alarm if the bag is not clamped properly, and the alarm will be lifted after the bag is clamped properly.

6) If the above alarm is removed or no alarm is issued, the bag will be fully drained. After a certain weight is put in, the bag holder will be lifted. At the end of the full flow, the material will start to be fed in a small flow.

7) Check the bag again after loading.Overweight alarm, underweight alarm and vibration alarm of weighing device may occur in the process of sampling inspection.

8) After weighing, tilt the bag holder, put down the bag full of starch, and enter the next weighing cycle.

2. Selection of Scheme

Now used in the production of quantitative packing scale, its control instrument is based on single chip microcomputer as the core of weighing control instrument, it can handle the input and output quantity is less, suitable for granular or powder material is not easy to moisture absorption packing control, due to the mechanical part of starch quantitative packaging machine is complex and requires more complex sequence control,At present, the existing SCM as the core of the control system is difficult to be competent, and the complex timing sequence of action control is the strength of PLC, but the interaction ability of PLC is weak, and the cost of high digit simulation board is higher;As a complete weighing control system, there are many parameters need to change often, that is, the need for rich keyboard ability, which is the general single-chip application system is good at, so the characteristics of both desirable, the whole system is a PLC subsystem and single-chip subsystem.This is the first scenario.Another scheme is that the whole system adopts STD bus industrial computer.Because STD bus industrial computer has rich input and output templates, it is easy to form the system, and its reliability is high, but the limited number of A/D templates it provides can not meet the requirements of weighing.The third scheme is to adopt the industrial computer system based on PC bus.As based on PC bus industrial computer also has A lot of input file template, losing and can image on the display to show the working state of the field, and can easily for the man-machine dialogue, its interactivity is one of the best, but the simulation of the plate of A/D converter digits for 12 commonly, again high number of bits, the high cost of system, also to the requirement of the highest.After comparison, we choose the first option.

3. System Implementation

In the specific implementation process, we chose the performance of Samsung's PLCSP-100, which is relatively high price, by which it is responsible for the mechanical part of the action control and monitoring of some on-site state switches.

Weighing part adopts our own design of the single chip microcomputer as the core and quantitative weighing controller.

3.1 PLC subsystem

PLC adopts 3 input modules and 3 output modules, which are explained as follows:

INT module 1: full flow signal, pressure tank material level, closure of stop flow door, closure of bag clip, air pressure, trickle signal, nozzle cleaning permit, conveyor belt start.

Int module 2: tilt bag holder, release approval, delay relay of upper bag holder, alarm of weighing device, nozzle cleaning, sampling signal, loose bag delay selection, residual discharge signal.

INT module 3: power supply, operation signal, LED flashing signal, weighing cycle interval signal.

Out module 1: stop flow door, bag preparation, pressure tank discharge, start weighing signal, delay relay of upper bag bracket, lower bag bracket, upper bag bracket, cleaning nozzle.

Out module 2;Tilting bag holder, opening bag clip, center alarm, material shortage indication, small flow conveying, closing door not opened alarm, full flow conveying, zero clearing start signal.

Out module 3: Small flow indication, full flow indication, alarm when bag clip/weighing hopper is not ready, correct bag position indication, bag clip closing indication, ready indication.

The whole working process is controlled by PLC program.

3.2 Weighing controller subsystem

It includes switching input and output circuit, signal conditioning and conversion circuit, microcontroller system (including program memory, EEPROM and watchdog circuit, real-time clock, configuration DIP switch), keyboard and display circuit, printer.

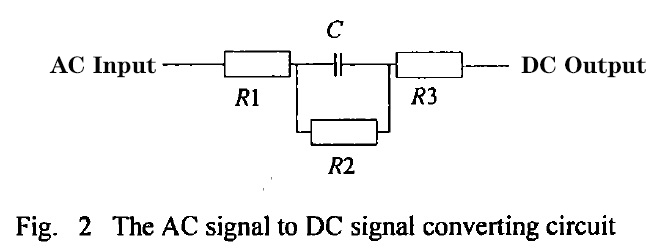

1) AC switching input and output circuit: the output signal of the weighing controller is sent to PLC, and the output signal of PLC is input to the weighing controller.The AC input in Figure 2 can be a field switch or a PLC output.Control output using solid state relays.

2) Signal conditioning and conversion circuit: the weight signal converted by the weighing sensor is amplified to the amplitude accepted by A/D converter, and then converted into digital signals that can be processed by MCU by A/D converter.

3) MCU system: as the core of the weighing controller, it accepts the data of A/D converter for filtering, display and judgment, and carries out full-stream and trickle-stream output and some alarm output;Receive the data input by keyboard, carry out the necessary code transformation, and store the necessary data in EEPROM;Switch to different levels of program according to configuration.

4) Printer: it can print time, batch, cumulative bag number and cumulative weight at any time.

5) Keyboard display module: complete human-computer interaction function and status display function, a total of eight digital tube display and some status indication, there are 32 keys, including 10 number keys and 22 function keys, to give users a convenient operation interface.22 function keys include: data extraction, data storage, batch count, bag check, menus, zero self-adjustment, automatic compensation, weight, tare weight, batch number of bags, preset trickle weight, compensation number, identification number, weight, bagging bagging units, printing, testing, reset, run, maintain and residue emission, alarm for confirmation.

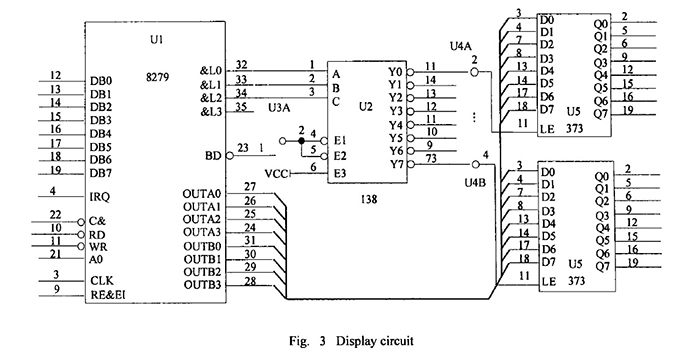

Due to static display of digital tube light, but the information displayed, less than the static and dynamic way to display information, but not bright digital tube, digital tube display circuit so the calculation of dynamic and static combination of circuit, dynamic scan it in 8279, to make static latch 74 ls373, coupled with the corresponding decoding control circuit, the concrete circuit is shown in figure 3.Other circuits are standard circuits and will not be described further.

3.3 Connection between PLC subsystem and weighing controller subsystem

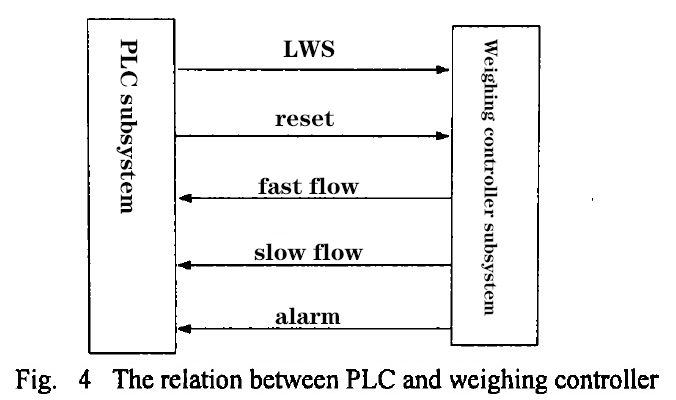

The connection between the PLC subsystem and the weighing controller subsystem is shown in Figure 4. In the past, the control action sent by the weighing controller is first transmitted to PLC, and then the PLC directly controls the executive device.The weighing controller also sends alarm signals to PLC according to the "short trickle", "slow cycle", "overweight", "underweight" and "vibration of weighing device" in the weighing process, and the warning light is connected by PLC. At the same time, the weighing controller displays the specific alarm type.According to the timing sequence action, PLC issues the weighing controller to start weighing and clear zero command.

4.Three-level access to system working parameters

The working parameters of the system set up three access rights for different levels of use.The third-level parameters have the highest level of access. They are those parameters that do not need to be changed frequently. These parameters are mainly set according to the mechanical equipment condition and production requirements.Generally by the production process personnel implementation.Must open the control cabinet, change a certain hardware configuration, and then use the button to change the sequence.These parameters such as "sampling bag number", "overweight upper limit", "overweight lower limit", "full flow stabilization packing time", "small flow stabilization packing time" and so on.In the secondary parameter access, the parameters often used in the operation can be set arbitrarily according to the need, such as "preset weight", "tare weight", "small stream weight", "compensation weight", "batch count" and so on.This level of parameter can be set by the instrument operator through the keyboard password control, without changing the hardware configuration.Therefore, its permission level is lower than three levels.For primary parameter access, it must be when the parameters of secondary and tertiary access are correct.At this level, all parameters placed in the secondary access can be called up by the operator and selected according to field conditions.Its authority is only the choice of two calculations and experimental proof that the large deformation straightening scheme has higher correction level set parameters, and cannot be changed, so the authority level is the lowest.

5.conclusion

The weighing and packing controller presented in this paper makes full use of the characteristics of PLC and MCU, so that the controller can not only meet the requirements of more complex timing control, but also give a user-friendly interface, and provide three parameters access level, which is convenient for users to manage the whole system, so that the system works in the best condition.The controller not only meets the needs of starch packaging, but also can be used for similar materials packaging control.

NOTICE: This site is reproduced by the editor of this website. The purpose of the reprint is to transmit more information. It does not mean that this website agrees with its views and is responsible for its authenticity. If you are involved in the content, copyright and other issues, please contact us within 30 days, we will delete the content in the first time! [Declaration] The copyright of this article belongs to the original author. The content is the author's personal opinion. This site is only for reference and does not constitute any investment and application advice. This site has the final interpretation of this statement.

Contact: Celia

Phone: +86-13825212800

Tel: +86-13825212800

Email: sales3@meterforall.com

Add: Floor 6 ,Building 11,Longbi Industrial zone, Bantian Street, Longgang District, Shenzhen, China